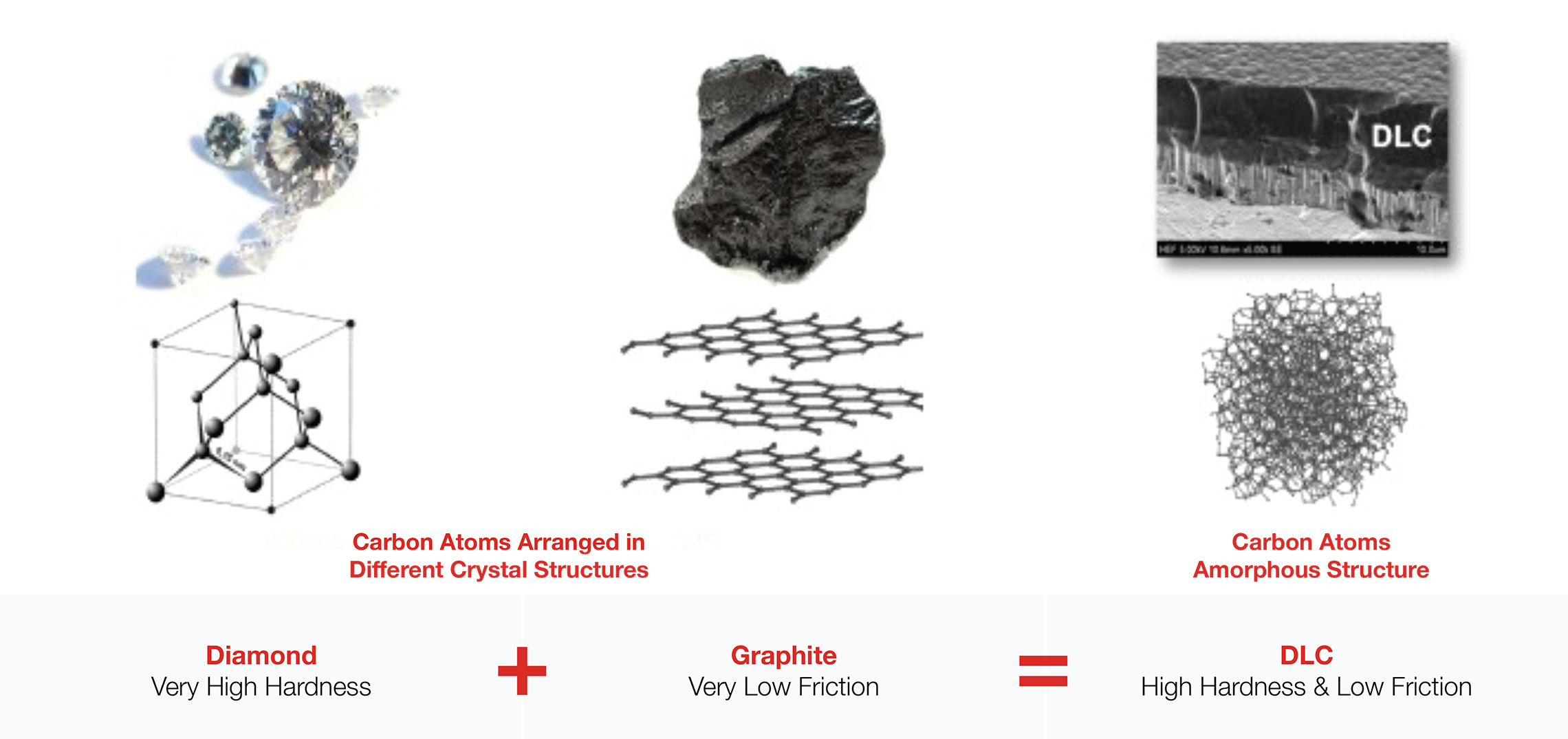

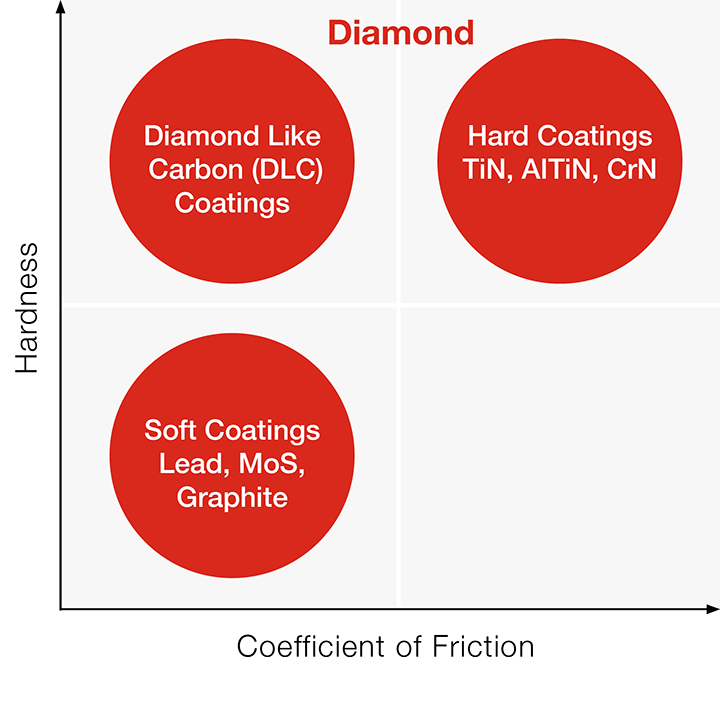

Diamond Like Carbon (DLC) coatings, a new technological advancement of PVD + PECVD coatings, has been widely successful in the commercial industry. Calico's carbon-based coating has extreme hardness due to the diamond crystal structure and is soft and lubricious due to the graphite crystal structure. Combining these two structures reduces the coefficient of friction by 200%-500% compared to traditional tribological PVD coatings. Our DLC coatings are generally amorphous (without typical crystal structure) and can be deposited using an expansive range of processes with elements like hydrogen and metals such as chromium. These integral components and techniques have an outstanding impact on the properties and structures of the DLC coating.

The properties of DLC coatings in terms of increased hardness, coefficient of friction, roughness, adhesion level, load carrying capacity, resistance to humidity influenced degradation, fatigue tolerance, etc. can be personalized over a varied range depending upon deposition parameters, deposition technology and the combination of materials making up the DLC coating. Calico's Diamond Like Carbon (DLC) coatings are in a dense, metastable form of hydrogenated amorphous carbon (a-C:H) containing significant SP3 bonding.

Calico Coatings is offering the CERTESS®CARBON line of Diamond Like Carbon (DLC) coatings. The DLC process of bonding carbon and hydrogen confers valuable "diamond-like" properties such as mechanical hardness, low friction, optical transparency and chemical inertness. This new advancement in PVD + PECVD (plasma-enriched CVD) coatings has led to the development of customizable DLC coatings. These DLC coatings can have many different combinations of properties that promote high load-bearing capabilities, making them the most suitable selection for improving the performance of engineered parts. DLC coatings are typically bio-compatible and appropriate for food-contact and medical applications. The soft and lubricious surface has great discharge properties, making these coatings a good choice for plastic processing applications.

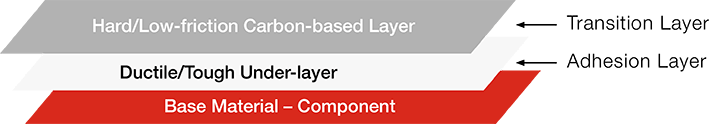

These DLC CERTESS®CARBON coatings meet the standards of many different operating conditions used for automotive and other general manufacturing applications. Calico has developed a group of DLC coatings that include several layers of different materials such as Cr, CrN, W, WCC and Si with a top layer of amorphous carbon with hydrogen. Calico offers a selection of under-layer materials so our clients' needs such as adhesion requirements, wear mode, contact mode, friction regimes faced during operation, load carrying capacity and other metallurgical sensitivities can be met.

All Calico DLC coatings can be made-to-order based on terms of hardness, coefficient of friction, roughness, adhesion level, load carrying capacity, resistance to humidity influenced degradation, fatigue tolerance, etc. over a wide range depending upon deposition limitation, deposition technology and the combination of materials establishing the coating. There are many common variants of the Calico DLC CERTESS®CARBON coating as follows:

| Commercial Name | Architecture | Thickness | Hardness | Treatment Temp. | Maximum Use Temp.2 | Coefficient of Friction (Dry)3 | |

|---|---|---|---|---|---|---|---|

| CERTESS®CARBON DT | WCC | <5 microns | 10-15 GPa | <200°C | 400°C | 0.20-0.25 | More |

| CERTESS®CARBON DCX | CrN + a-C:H | <5 microns | 10-25 GPa | <200°C | 300°C | 0.10-0.15 | More |

| CERTESS®CARBON DCY | Cr+WCC + a-C:H | <5 microns | 10-25 GPa | <200°C | 300°C | 0.10-0.15 | More |

| CERTESS®CARBON DCZ | CrN + WCC + a-C:H | <5 microns | 10-25 GPa | <200°C | 300°C | 0.10-0.15 | More |

| CERTESS®CARBON TC | CrN + taC | <2 microns | 20-65 GPa | <200°C | 350°C | 0.10-0.15 | More |

General remarks: All given data are approximate values, they depend on application, environment and test condition:

|

|||||||

What is DLC?

Diamond-Like Carbon, commonly referred to as DLC, is a family of carbon-based coatings that has extreme hardness due to the diamond crystal (tetragonal) structure and is soft and lubricious due to the graphite crystal (hexagonal) structure. DLC is amorphous in nature (does not have a crystal structure. DLC is a technological advancement of Physical Vapor Deposition (PVD) + Plasma Enhanced Chemical Vapor Deposition (PECVD) coatings that has been widely successful in the commercial industry.

Is DLC a type of PVD coating?

DLC coatings are deposited using a Plasma Assisted Chemical Vapor Deposition (PACVD) method. Unlike the PVD method which involves physically depositing the solid target material source onto the component surface, PACVD involves a precursor gas source (hydrocarbon) that is broken down into carbon and hydrogen atoms in plasma and deposited as DLC on the component surface in an amorphous fashion.

Is DLC directly applied to component surfaces?

DLC coatings are generally applied after a PVD underlayer such as Titanium (Ti), Chromium (Cr) or Chromium Nitride (CrN), or a combination has first been deposited on the component surface. The selected underlayer depends on various factors such as hardness of the component surface (substrate), bonding characteristics with the substrate, load bearing requirements of the application, and is determined based on the application and performance requirements.

What is a typical deposition temperature for DLC coatings?

DLC coatings are deposited at relatively low temperatures below 200°C. Calico’s technology allows these coatings to be applied at around 170°C. With our plasma enhancement technology, we can deposit at these low temperatures, ensuring there is no distortion or change in core properties of the component being coated. Thus, precision components with tight dimensional tolerances can be coated with DLC without any concerns.

What is the general DLC coating thickness range?

Total coating thickness, including underlayer, is uniform and ranges from 1 to 5 microns. The exact coating thickness within this range is determined based on the application and performance requirements.

What is the hardness of DLC coatings?

DLC coating hardness can range from 1500 - 3200 HV, depending on the type of DLC coating and choice of underlayer.

What are the main benefits of DLC coatings?

What is a typical friction coefficient value achieved with DLC coatings?

Coefficient of friction is generally the ratio of the frictional force to the normal force when two bodies interact with each other. Applying DLC coatings helps to reduce friction for applications involving smooth, interacting surfaces. Lubrication plays a key role in this property as well. Typical friction coefficient range for components with DLC coated surfaces can be around 0.10 to 0.25 in a dry-condition and less than 0.10 in a lubricated condition.

Are there any limitations of DLC coatings?

DLC coatings, primarily due to carbon, cannot be used when service temperatures exceed 350°C.

Can you remove the DLC coating and re-coat components if required?

Yes. DLC coating can be removed or stripped if required. While the DLC layer can be removed within the same coating chamber using a reactive plasma-based process, removal of the PVD underlayer(s) requires components to be immersed in a chemical solution for a certain amount of time. The components may require additional polishing before recoating.

Are there different types of DLC coatings?

DLC is a family of ultra-hard, thin-film, carbon-based coatings that can be broadly classified into:

Hydrogenated DLC, represented as a-C:H (amorphous carbon, hydrogenated). In this category there are several coatings with different underlayers – but all have the same a-C:H top layer. The full range of hardness for coatings within this family is 1000-2800 HV, but the typical range is 2000-2200 HV. For further details, please refer to the DLC Coatings section of our website.

Non-Hydrogenated DLC, represented as ta-C (tetrahedral amorphous carbon). This coating is deposited from solid carbon sources, rather than a gaseous hydrocarbon (as for the a-C:H coatings) precursor. The specific arrangements of the carbon atoms within the ta-C coatings results in them being at least 20% harder than the standard a-C:H coatings and can withstand operating temperatures of up to 450° C – which is about 100° C higher than the maximum temperature resistance of a-C:H coatings.

What are typical applications of DLC Coatings?

DLC coatings are used for a wide range of applications. DLC coatings are especially useful where a combination of both wear and friction reduction is required. DLC coatings also offer a cosmetically pleasing charcoal finish. Typical applications include:

What is CERTESS® CARBON?

CERTESS® CARBON is our line of DLC coatings. There are several options within the family of CERTESS® CARBON coatings so we can match you with the best one for your particular needs. These include: