Physical Vapor Deposition (PVD) coatings have a positive presence in a wide range of industrial, non-industrial and cosmetic applications due to their increased hardness, low coefficient of friction, extreme temperature resistance and a multitude of color ranges. PVD coatings can be applied to many different surfaces including; steels and other ferrous metals, non-ferrous metals, glass, plastics, rubber and elastomers.

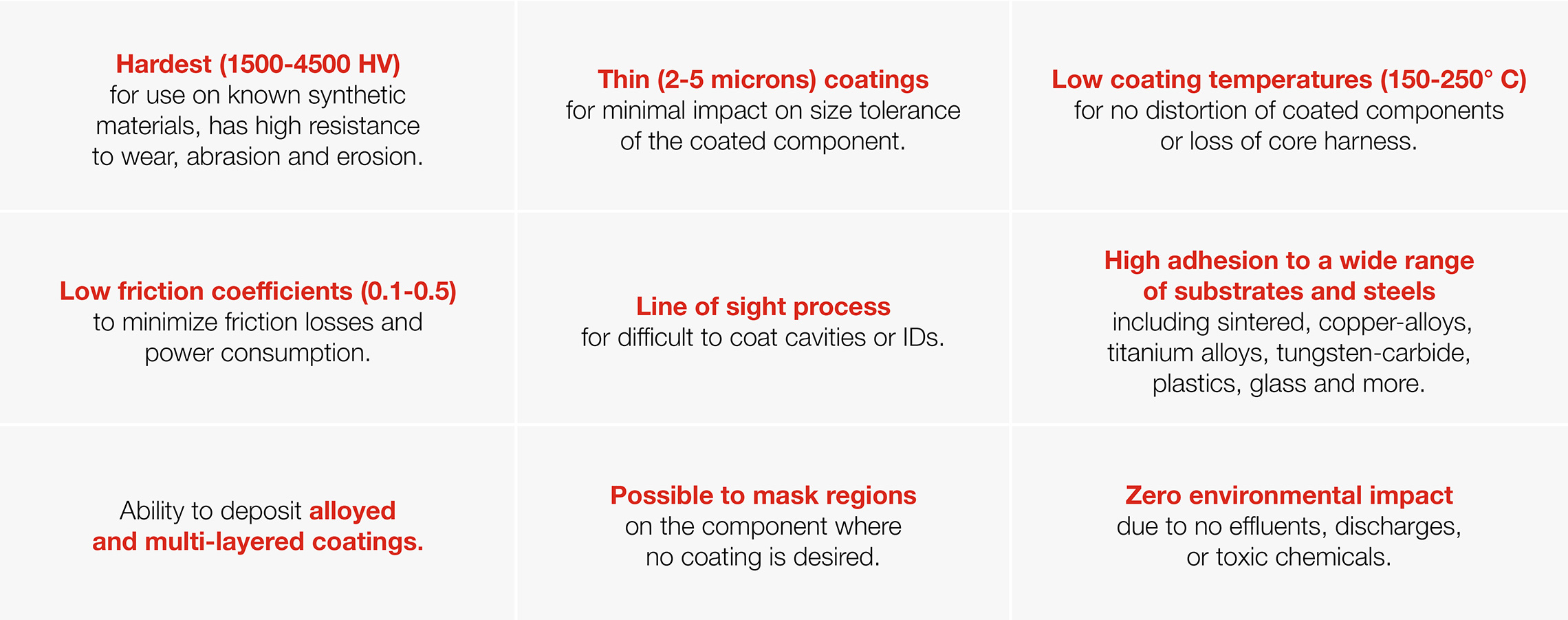

Calico's PVD coatings are sound, eco-friendly and customizable in structure. Our thin film technology also embodies our development in surface engineering. Our PVD coatings perform under extreme pressure to add value and help solve our clients' particular business challenges related to wear. The PVD systems and processes we have in place are designed for a broad range of parts and products used in the following industries: Aerospace, Automotive, Chemical, Diesel, Energy, General Manufacturing, Marine, Medical, Metal Forming, Military, Molds, Motorsports, Nuclear, Oil & Gas and Weaponry.

Calico Coatings is offering CERTESS®NITRO, an additional range of ultra-hard PVD coatings available to support all your wear challenges. Our PVD CERTESS®NITRO coatings contain the deposition of thin (2-10 microns; 0.0001" – 0.0004") films on the surface of parts and materials.

The table below shows a summary of properties such as hardness, typical coating thickness, deposition temperature and maximum usage temperature of CERTESS®NITRO PVD. Parameters such as deposition temperature are important to ensure that the component being coated is not exposed to conditions that are above its tempering temperature and that the base / core hardness is not compromised.

| Commercial Name | Architecture | Thickness | Hardness | Treatment Temp. | Maximum Use Temp.2 | Coefficient of Friction (Dry)3 | |

|---|---|---|---|---|---|---|---|

| CERTESS®NITRO Ti | TiN | <5 microns | 25-30 GPa | <200°C | 500°C | 0.20-0.25 | More |

| CERTESS®NITRO T | TiAIN | <5 microns | 25-30 GPa | <200°C | 800°C | 0.20-0.25 | More |

| CERTESS®NITRO TC | TiCN | <5 microns | 25-30 GPa | <200°C | 800°C | 0.20-0.25 | More |

| CERTESS®NITRO SD | TiBN | <5 microns | 30-35 GPa | <200°C | 800°C | 0.20-0.25 | More |

| CERTESS®NITRO X | CrxNy | <5 microns | 25-30 GPa | <200°C | 700°C | 0.20-0.25 | More |

General remarks: All given data are approximate values, they depend on application, environment and test condition:

|

|||||||